why do we excavate in construction

- Foundations of building

- Plinth beam plinth masonry

- The basement of the building

- Underground water tank

- Septic tank

- Laying drainage, water lines, electric cables, etc.

- Foundation of compound wall

- Footings of the main gate

- Earthing pit, etc.

REQUIREMENTS TO START EXCAVATION AND FOUNDATION WORK PROCEDURE

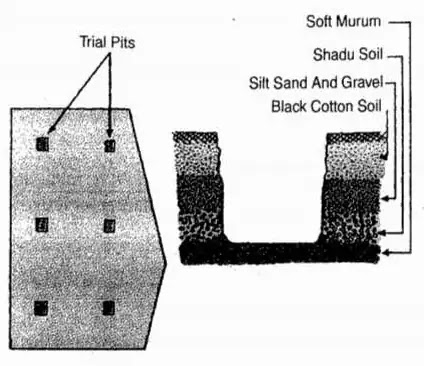

The stability and design of the building depend on the strata on which it rests. So, a trial pit per 400 sq.m. area of the plot should be made, to know the strata pattern.

- Black cotton soil

- Red Soil

- Silt, sand, and gravel

- Shadu soil

- Soft murum

- Hard murum

- Soft rock

- Hard rock

|

| trial pit study strata |

Generally, the size of the footing depends on the bearing capacity of the strata. The following table shows various soils and their respective approximate bearing capacities.

NOTE: The bearing capacities are given in table No. 21.1 are approximate and given on the basis of average strata, Actual bearing capacities of the strata should be derived by.

| SR NO | STRATA | SAFE BEARING CAPACITY IN TONNES/SQ.M |

| 1 | VERY SOFT, WET, PASTY CLAY | 0 TO 5 |

| 2 | BLACK COTTON SOIL DRY | 4 TO 10 |

| 3 | RED SOIL | 10 TO 30 |

| 4 | SHADO SOIL | 20 TO 30 |

| 5 | LOOSE GRAVEL | 15 TO 25 |

| 6 | MURRUM | 25 TO 45 |

| 7 | SOFT ROCK | 40 TO 90 |

| 8 | HARD ROCK | > 90 |

1. A static penetration test (SPT) – For soil and clay

2. Plate bearing test – For murum, rock.

During the execution of the work, the actual bearing capacities of the strata should be checked at the site, and approval for the same be secured from the Structural Consultant.

2. TESTING OF SOIL PRACTICAL NORMS AND LABORATORY TESTING

During excavation and foundation work procedure, it is necessary to study soil samples for finalizing the bearing capacity. Given below are a few observations for different strata.

BLACK COTTON SOIL

- Greyish black in color

- Heavy clay contents of unreliable quality

- Swells when wet and shrinks when dry

- Wide cracks develop when dry

- Termed as poor soil for foundations

RED EARTH

- Red in color

- Absorbent in nature

- When dry, turns to clay

- Forms hard lumps, not easily breakable

- The lump cannot be powdered by hand

SHADU

- Yellowish/whitish brown in color

- The intermediate stage between clay and sand

- Sand particles can be felt when rubbed

- It contains moisture when wet and possesses appreciable cohesion when dry.

- Termed as reasonably good soil for foundations

MURUM

- Red, brown in color

- Found in lumps/layers when excavated

- The lump is of irregular thickness, size, and shape

- Well compacted deposits when dry

- Can be broken, if forced by both hands

ROCK

- Generally found as the lowermost layer

- May be black, red or of any color

- Very strong, cannot be excavated with pick aхE

- Termed as very strong strata for foundations

BEARING CAPACITY OF SOIL

- A pit is excavated up to the strata which are to be tested.

- The bottom of the pit is leveled.

- The load is applied on the bearing plate, which is four times the designed load.

- The settlement is recorded every 24 hours.

- The recording is done till there is no settlement in 24 hours.

- Settlement under test load should not be more than 20mm.

- Loading can be done using cement bags or sandbags.

Some of the laboratory tests are given below for reference.

- Proctor compression test

- Moisture content determination

- Consolidation test

- Liquid limit test

- Shear test

- Shear box test

- Tri-axial compression test

- Unconfined compression test

- Penetration test etc.

Before starting the excavation and foundation work procedure, the engineer in-charge should prepare/ensure that the Architect issues foundation drawings. The points that should be covered in the drawings are as follows.

- The north line to set the building

- The side margins from the boundary

- The outer dimensions of the building

- The individual column/ wall – P.C.C. details

- The orientation of the column and thereby of the pit

- Overlapping of any pit with the other

- The assumed or derived bearing capacity of the strata

Excavation and foundation work procedure requires different types of tools. machineries and other equipment.

- STOOL

- Tikav with handle (pickaxe)

- Phavada with handle (spade)

- Ghamelas (mortar pans)

- Crowbar

- Chisels

- Hammers with handle

- Line Dori (Nylon string)

- Template (farma) for giving line out of the pit

MACHINERIES

- Bulldozer

- Excavator

- Tractors, dumpers trucks

- Compressors with jackhammers

- Drills and drilling equipment

- Water pumps (for de-watering)

MATERIAL

- Fakki (lime powder)

- Shoring material

- Blasting powder

- Blasting equipment

Depending upon the quantum of work and types of machinery available, the site in-charge should judge and employ the labor force, so as to complete the task at the scheduled time.

- The laborers have sufficient and sharpened tools.

- The dumping stack and location for excavation and foundation work procedures are easily accessible.

- The skilled and unskilled laborers employed are proportionate.

- There is an adequate supply of drinking water at the site.

- Child labour is not allowed to work on-site.

- A mukadam is employed to arrange for skilled and unskilled labourers.

- Hutments, if required, are provided.

Sometimes, site conditions restrict working mobility. This hampers the progress of work. Some situations are listed below.

- Trees coming across the pits

- Underground drainage or water lines coming across the pits.

- Electric or telephone cables crossing over the planned building.

- Excavated stuff needs to be stacked on public property.

- Strata if very hard. requires blasting.

On approval of the plan, various permissions from the authorities should be obtained immediately since it is a time-consuming job and may hamper the progress of the work is delayed.

- Estimate the excavated stuff to be re-utilized in filling, gardening, preparing roads, etc.

- As far as possible, try to carry away excavation and foundation work procedure and filling simultaneously, to avoid double handling.

- Select and stack the required material, so that other construction activities are not obstructed:

- Excess or unwanted material should be immediately carried away and disposed of using.

- Departmental labour

- Tractor

- Trucks

8. ARRANGEMENTS FOR SAFETY PRECAUTIONS

The site in charge must ensure that proper precautions are taken during the excavation and foundation work procedure, to protect the labourers from injuries and to protect the structure from any damage.

- Nails should not be lying around, after the completion of line-out of side rails.

- Shuttering materials required for P.C.C. and footing should not be left around. Ensure that nails are removed and planks are stacked at a convenient place.

- Labourers engaged in excavating hard rock by chiseling should wear gum-boots.

- Laborers working with jackhammers should wear helmets, gloves, and gum-boots for protection.

- The approach road should be firm and sufficiently broad.

- The movement of the trucks should be away from the pit.

- When the truck enters the site, the cleaner should get down to guide the driver.

- All electric equipment connections and the earthing should be checked.

- The de-watering pump should be kept on a firm foundation and shifted carefully, whenever required.

- Proper lighting arrangements should be made for the work at night. This also helps the night watchman, to guard the site material and equipments.

- Ladders should be provided to climb in and out of the pits.

House Construction Step-3 | Excavation and Foundation | How to Build Home?

PRECAUTION IN EXCAVATION BLACK COTTON SOIL SHORING FOR EXCAVATION

Collapsing of the sides is one of the major problems while excavating black cotton soil, making it a risky and dangerous job. The precautions to be taken are listed below.

- The pit size for excavation should be a minimum 30cm more than the P.C.C. size, on all sides.

- If the depth increases, the pit size should also be increased accordingly.

- In black cotton soil, as the depth increases the sides begin to collapse. To prevent this, shoring should be done or a larger pit may be excavated in slopes or in steps as shown.

- Never start excavation of two adjacent pits simultaneoușly.

- Excavated black cotton soil should be removed from the site. It should not be used for refilling.

- As black-cotton soil is very soft, more labour force can be applied to excavate, collect and dispose of the excavated material.

- Avoid excavation and foundation work procedure on rainy days.

EXCAVATION IN SOFT HARD MURUM

- As the depth of excavation increases, the strata change. Generally, harder strata is found at greater depths.

- This can be identified while applying the force to excavate.

- The change in strata can also be judged by the color difference and handling of the excavated stuff.

- Tools should be sharpened as while excavating soft and hard murum.

- The pit with soft/hard murum should be flooded with water a day before the excavation and foundation work procedure. The strata absorb water and become relatively soft, making the excavation easy.

- Pit size may be exactly the size to suit the form of work of P.C.C.

EXCAVATION IN ROCK

1. CHISELLING

- When there is almost no penetration and using tikav does not yield results, chiselling and hammering are adopted to excavate the rock.

- Wedging by crowbar can also be applied, in the case of laminated rocks.

- For the breaking of hard rock, pneumatic breakers are also used.

- Excavation in hard rock involves more skilled laborers than unskilled ones.

- While excavating in hard rocks, strict safety precautions should be observed.

2. BLASTING

If excavation in hard rock is to be carried out on a large scale, e.g., construction of dams, roads, canals, laying of pipelines, etc., then blasting is often the only means of breaking the rock quickly and at a reasonable cost.

However, it is not widely used for building excavation in urban areas.

MASS AND DEEP EXCAVATION LIKE BASEMENT

For the basement, swimming pool, etc. strata is not the only criterion for deciding the depth of excavation. The formation level plays an important role and leads to mass deep excavation and foundation work procedures.

- This type of excavation needs special attention.

- The quantity being large, more than one gang can be employed for the job.

- Allocation of work to different gangs should be such that maximum output in minimum time is achieved.

- Levels should be taken prior to and after the completion of work for billing purposes.

- If the excavation goes below the groundwater table, make adequate arrangements for pumping out the water.

- For lifting out the excavated material either ramps or steps should be provided, at the time of excavation and foundation work procedure.

- A corner of the pit is excavated further, to collect the water in one place.

- The de-watering pump required is of higher capacity, with long suction and delivery hose pipes, since shifting from one place to another is not possible.

EXCAVATION IN FLOWING WATER

TYPES OF FOUNDATIONS

Foundations used in building construction are broadly classified as shallow foundations and deep foundations.

These can further be divided into

1. SHALLOW FOUNDATIONS

- Single or spread footing

- Combined footing

- Rafts or mats

A. SINGLE OR SPREAD FOOTING

- Most common and the simplest type of foundations.

- Distributes the load or weight over a sufficient area on the foundation bed.

- It is rectangular or trapezoidal in shape.

- Suitable for shallow depth of foundation having moderate bearing capacity.

- This footing supports more than one column.

- It is required for columns at the expansion joints.

- For columns on the boundary line of the plot or when footings of two columns overlap each other.

- Combined footing may be rectangular or trapezoidal in shape.

- It is recommended when the safe bearing capacity of the soil is low (poor) and columns carry a heavy load.

- It is very useful for the strata, where there is a possibility of uneven settlement.

- Footings of a group of columns or all the columns in the structures are combined to form a raft foundation.

- Recommended for soils that have a higher water table.

- Raft foundation consists of a thick R.C.C. slab covering the entire area at the bottom.

- Thus, the raft foundation spreads the load of the building over the whole plan area and reduces the foundation pressure to the minimum.

These foundations are used for transferring the load firm strata underlying deep below. For example, well foundation, pile foundation, etc. For building construction, pile foundations are commonly used.

Pile foundation is R.C.C. column (circular) cast-in-situ or pre-cast, driven in the ground.

The two main types of pile used in building constructions are

- End bearing piles

- Friction piles

WHY PILING IS REQUIRED?

- When soil is soft and there is no solid substratum for the foundation at a reasonable depth.

- When the raft foundation is very expensive or practically impossible.

- When the building carries heavy concentrated loads.

- When the building is constructed along the seashore or river bed.

A. END BEARING PILES

- These piles are used to bear vertical loads.

- They are driven into the ground until a hard bed is reached.

- The load of the superstructure is transferred to the hard strata through these piles.

- These piles act like columns carrying a structural load, below ground level. The bearing piles may be cast-in-situ or may be pre-cast.

- For pre-cast piles, the piles are driven in the ground either manually mechanically.

- For cast-in-situ piles, the bores of the required diameter are excavated until the hard strata is reached.

- The bore is cleaned, de-watered and the pile cage is slowly lowered down to the hard strata.

- As the depth is more, the concrete is poured through tremie or shoots to avoid segregation.

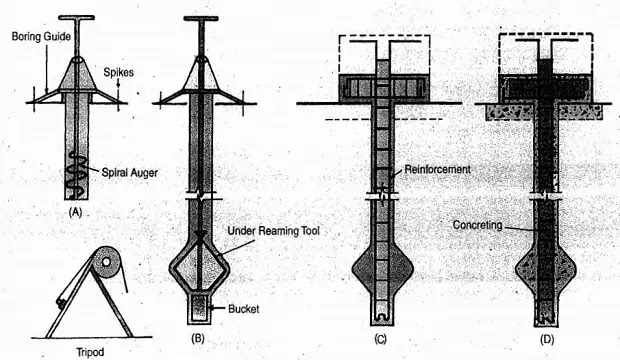

- Set the tripod in the exact position on the center of the pile.

- Make the initial boring to hold the temporary casing.

- Drive the temporary casing up to hard strata.

- Bore up to hard strata with bailer (sludge pump).

- Remove muck and water from the sludge pump.

- Chisel the hard rock with an appropriate heavy chisel to have a socket of a minimum of one diameter of pile diameter in hard rock.

- To avoid side collapse use Bentonite powder and water while boring in soft strata.

- Measure the depth of the pile bore at regular intervals of 30 minutes.

- Approve the strata only when penetration is less than 5cm for 30 minutes of chiseling.

- Cut the reinforcement cage according to depth and lower it down into pile bore.

- Lower the tremie pipe (200 mm diameter) in pile bore. Keep the tremie pipe bottom approximately 30 cm above approved strata. Install hopper on the top of tremie.

- Prepare concrete by mixer and transport to pile location by wheelbarrow.

- Pour the concrete in the hopper to its full capacity.

- Remove the steel plug so as to make the proper flow of concrete inside tremie and thereby in pile bore.

- Ensure that the tremie pipe is embedded in concrete at least 1.5 m, repeat the procedure till concreting is done up to existing G.L.

- Remove Tremie and Hopper.

- Pour extra concrete inside the pile bore, to ascertain no cavities are left.

- Lift the temporary casing gradually and shake the reinforcement cage to ensure for proper cover and compaction.

|

| instruments for under reamed pile |

QUALITY CHECKS

- Mark the reference point before driving the casing.

- Check the distances of references from time to time.

- Collect and check strata after every 30 minutes.

- Ensure anchorage with minimum depth in Hard strata equal to the diameter of the respective pile.

- Ensure that the last 30-minute penetration in hard strata is less than 5cm.

- Use M 20 grade concrete with a stump of 150 mm.

- Cast 6 concrete cubes for every batch of concrete.

- Check the compressive strength of the cube at 7 days and 28 days of curing.

- Maintain the logbook for every pile for the following details.

- Depth of Pile.

- Chiseling Hours.

- Theoretical and Actual consumption of cement.

- Date of concreting.

There are various types of friction piles, however, most common and widely used in building. construction is an ‘under reamed pile.

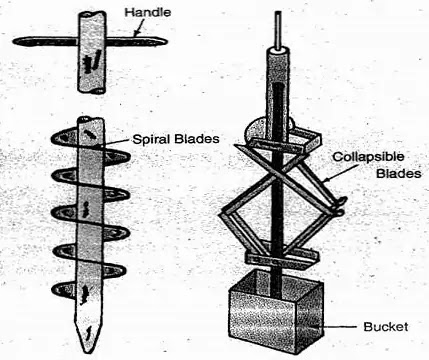

- Auger with special blades to excavate the pile hole.

- A reaming tool to form the bulb.

- Bucket to collect and remove the excavated soil from the bulb.

- Extension rod to extend the length of the reaming tool or auger.

- Tripod and pulley block – to take out the reaming tool or auger from hole.]

WORK PROCEDURE FRICTION PILES

- Give the samples of the soil excavated from the trial bore, at various depth to the Structural consultant.

- Collect the R.C.C. drawing from the Structural Consultant.

- Mark the center of the pile on the ground.

- Excavate about 30cm of the soil manually.

- Erect the tripod stand exactly over the pile center.

- Auger having helical blades are inserted in the bore.

- The diameter of the blades goes on increasing and it is equal to the bore diameter at the top.

- Auger is rotated manually, applying downward pressure.

- After sufficient depth (1.00m) excavated auger is taken out with the help of a chain and pulley block.

- Mud and water should be removed from the bore and the procedure should be repeated till the desired depth of excavation is reached.

- Approximately at every 2m of excavation, a reaming tool with a bucket is inserted in the bore to excavate a bulb as shown in the figure.

- After the formation of a bulb, the tool is pulled up, and excavated soil collected in the bucket is removed.

- The Pile cage is lowered down as per the drawing and design.

- Maintain the pitch of spiral stirrups as per the drawing.

- Ensure the concrete covering to the main steel, plumb of the cage, etc.

- Pour concrete of the desired grade.

- Mix the concrete with the mixer and using a concrete platform.

- Compaction may be done by rodding.

- After casting the bore, a concrete pile cap or plinth beam is cast over the pile as per the given design.

- From this cap/beam the columns of the superstructure should be taken out.

- Keep the pile bars including spiral stirrups above the G. L., for required lap length.

|

| storage in construction at under reamed piles |

DEWATERING WORK

Sometimes while excavating, water is reached at an intermediate stage, before reaching the required strata.

Work cannot proceed unless the water is removed. If the water is locally stagnant, it can easily be removed manually. But in case of a source of water or a high water table, case pumps are installed for de-watering.

The following points should be attended to while de-watering

- Select a pump of adequate capacity (suction and delivery).

- Provide suction and delivery pipes as specified.

- Check the availability of fuel/electricity.

- Provide gate valves for proper control.

- Check the working of the foot valve. Clean it before use.

- Cover the foot valve with chicken mesh as a filter media.

- Install the pump on a proper foundation.

- Check the electric connection and earthing.

- While shifting the pump from one pit to another, disconnect the electric supply.

- The pump should be covered and no water should enter it.

- Check the rotation of the flywheel as per the arrow shown on the pump. If it is reverse, check the phase.

- Never run the pump dry.

- Priming should be done if required.

HIGHLIGHTED POINTS TO BE OBSERVED DURING EXCAVATION AND FOUNDATION WORK PROCEDURE

- Study a sufficient number of trial pits for exact data of the strata.

- Confirm the strata in consultation with the consultant, before proceeding for P.C.C.

- Excavate the foundation pit at the same level and avoid resting of the footing on sloping strata.

- Remove all the loose excavated material and clean the pit.

- Give the size of the excavation pit to avail of the working space for the carpenter to fix and remove the shuttering box of P.C.C.

- Carry out shoring in case of black cotton soil, to avoid accidents.

- Insist on the foundation drawing to be incorporated with the centerline plan to cross-check the overlapping of foundation, the orientation of the column, etc.

- Dewatering of the pits should be well planned and dewatering should be laid in a stormwater drain.

- Necessary permission should be obtained prior to shifting underground service lines such as drainage, electric cables, water lines, etc. before the work begins.

- Necessary approvals to cut the trees. stock (dump) the material on public property etc. should be obtained from the local authorities.

- Permission to shift the overhead service lines should be obtained.

- Safety precautions should be observed while excavating.

- Sufficient light arrangements should be made for work in the night shift.

- Ensure that the foundation of adjacent buildings is not exposed while excavating the basement.