Therefore, control over the cost of material components automatically reduces the cost of construction.

Control on the cost of the material components can be achieved.

- Estimating the exact quantity and requirement of the building material requisition procedure. Optimum use of the materials received on the site.

- Purchasing the exact quantity and type of material as per the technical requirements of the item.

- Placing the exact quantity and grade of material as per the technical requirement of the item.

- Placing the order after preparing a comparative statement of the advantages of various products, in terms of cost and quality.

- Maintaining and updating of stores and reconciliation of materials.

- Utilization of excess materials and equipment on other sites.

- The purchase engineer/purchase department plays an important role in construction activity.

- An order placed without enough information may lead to either inferior quality of work or an unnecessary increase in the cost of construction.

- Purchase Department should, therefore, have detailed information about the various products available in the market.

- An in-depth market survey for the quality and availability of similar materials of different companies could be undertaken.

- Comparative percentages of product costs for some basic items are given below to demonstrate the variance between the costs of material.

- All comparative statements are based on rates valid as of 1st Feb. 2001 in Pune.

|

| Material rates |

Building Construction material know how and requisition procedure

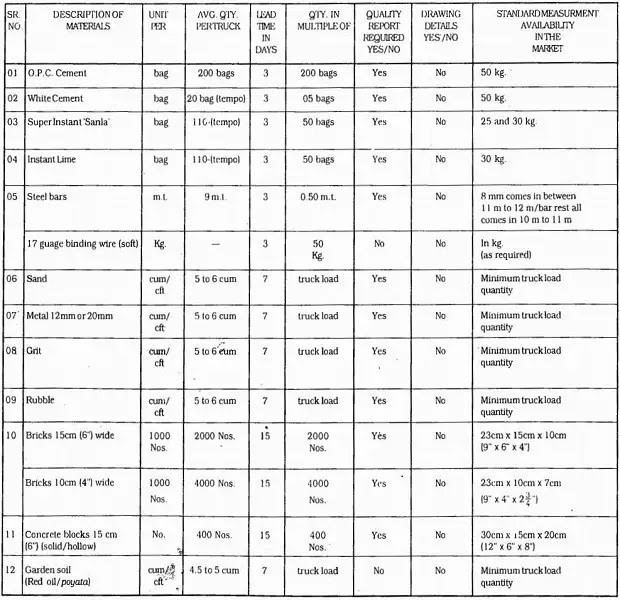

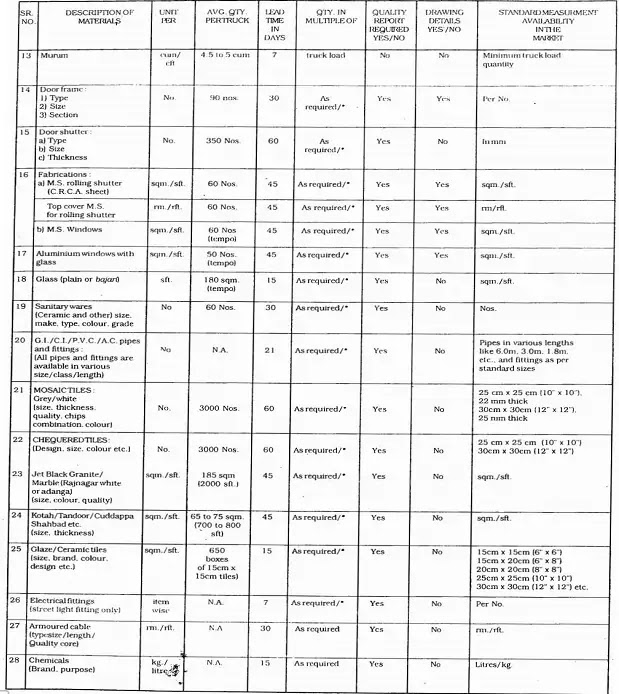

building material know how and requisition procedure is required to help the engineer write requisitions (indent) for each material. The description, specification, unit, quantity, etc. of each material should be universal to the entire organization, to eliminate the chances of wrong purchase. The minimum details required for indent should be complete in all respects as given below.

How to Create MATERIAL PURCHASE REQUISITION in MS Excel.

1. DESCRIPTION OF MATERIAL

To avoid purchasing of wrong materials, leading to wastage and unnecessary transportation charges for replacement, a specific description of the item is required. (For example)

Size 560mm x 400mm (22″ x 16″)

Colour pink

Quality as per approved specification.

Here, size and color are important while purchasing the particular material as per the requirement. It may vary from site to site.

The building material know-how and requisition procedure charts row the average quantity per truckload for economical consideration, since transporting charges for a full truckload prove cost-effective, while the indent is being raised.

Lead time is the minimum time required for delivery of (for some items) material after placing the order. It takes into consideration the supplying time as well as the time taken for dealing and negotiating with different agencies. To avoid delay in the delivery of materials. every engineer should account for lead time while submitting the indent. The indent of any material should, therefore, be given in advance as per the lead time of each item.

This column shows the quantity of each material to be ordered in multiples of truckload/tempo load, flat wise, building wise, project wise, or as per the requirement of each site. If the material is ordered for the complete building/entire flat, it is easy to maintain the records on-site and for reconciliation. of each material after utilization.

- It has been discussed in the previous chapters that the quality report of each material be sent along with the challan to the accounts department, This helps the site staff in ensuring the quality.

- Otherwise, it becomes difficult to replace defective materials at the last minute. This delays the work, even though the material has been received on time, Also.

- The supplier raises the bill after delivery and the payments may have been made by the accounts department as per the quantity challan received from the site.

- Ultimately, the company ends up making payments for damaged material and runs losses due to time factors. So quality reports should be submitted along with the challans.

7. DRAWING DETAILS REQUIRED (YES/NO)

- For certain materials, drawings have to be attached with an indent for clarification, while placing the order to the supplier.

- For example M.S. rolling shutter, M.S. windows, M.S. grill, Aluminium windows door frame fixing, etc.

- If you order M.S. window of size 1.2m x 1.2m (4’0’x 4’0″) it will be of no use for the purchasing department. Drawings attached with details like a section to be used, size of guard bar, the spacing of guard bars, etc. will prove much more useful.

8. STANDARD MEASUREMENT AVAILABILITY

- The Engineer should know the standard sizes of materials available in the market like standard packing. the standard length of material, the standard size of the material, standard packing boxes, etc.

- For example : G.I. pipes are available in 6.0 m length, M.S. angles are available in 6.0 meter length, steel bar length varies from 10.5 m to 12.0 m (35 to 40), coal tar in 5 kg., 10 kg. tin, plywood shutters in 81 x 203 cm (32″ x 80″), 66 x 203 cm. (26″ x 80″) etc.

- This helps in writing the indent of any material. as orders can be raised directly from the purchase department as per the requirement.

- Otherwise, the purchase department will have to clarify the requirement with the site engineer.

- For odd sizes/odd lengths/odd quantity building material know-how and requisition procedure standard measurements availability is essential to write indents or make estimates of the work.

- They may be subject to change as per the manufacturing policies. The engineer will be notified of these changes by the purchase department.

HENCE ALL ENGINEERS SHOULD STUDY MATERIAL READY RECKNOR CHART BEFORE WRITING INDENT OF ANY MATERIAL.

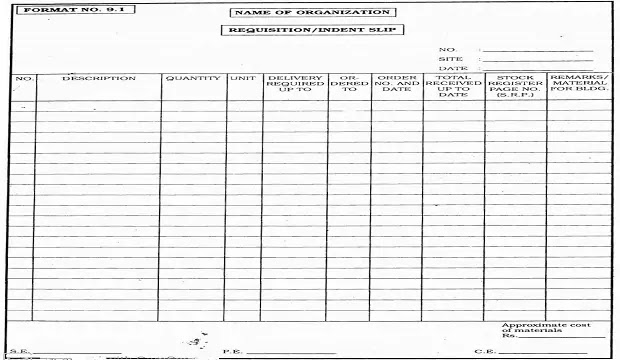

INDENT (REQUISITION) AND IT’S PROCEDURE

1. WHAT IS MEANT BY REQUISITION

- Requisition (indent) is the requirement of material, submitted in a standard format, by the site to the purchase department with self-explanatory information about the materials.

- The indent should be given well in advance as per the work schedule of each site.

- Material is purchased as per the indent received from the site.

- Here, it should be reiterated that the 70% cost of the building is the material cost. So, while purchasing the material extreme care needs to be exercised.

- It is important to raise the correct indent for purchasing material.

- A standard procedure should be devised for placing an indent, with provision for checking by various authorities in the organization at every stage.

2. HOW TO WRITE RFQUIETION OF MATERIAL

- Here some guidelines are given or writing indent for purchase of material.

- Decide on particular days in a week when indent can be sent to the H.O./purchase department.

- The indent should be written by J.E./S.E. and should be submitted to P.E. for checking.

- Estimation should be done in advance for the quantity of indent.

- It should be written out neatly.

- The Project Engineer should check the self-explanatory specifications of material, lead time, delivery schedule, quantity requirement, and other requirements as per the indented format.

- The approximate cost of the material should be written on the right-hand side of the indent.

- The indent should be written in duplicate and the first copy should be submitted to the H.O.

- Indicate the site name date clearly.

- If the material is required for extra amenity then write debit/credit note No. in remark column for easy checking &t every level.

- Follow the procedure flow chart for the submission of indent.

- In the indent format order to, order No, and date column is written by purchas: department for reference.

- The total material received up to date column can serve as the receipt of that material from the commencement of the project.

- The stock register page number is the stock book page number for the ledger entry of that material.

- In the remarks column, material required for a particular building, par.: a building should be noted down.

3. CHECKING OF REQUISITION FY PURCHASE DEPARTMENT

The purchase department will check the indent for the following

- All materials are easily available.

- Possible delivery schedule (practical).

- Building a name for which material is demanded.

- If extra amenity then debit/credit note No. and a sign of maintenance department.

- Quantity of material for truckload or size of material available in the market.

- If the size is variable from the market, availability/non- availability in economical sizes to be confirmed with the site engineer for alternative options of size/quantity.

- Specification of material required for a particular site (approved).

- Grade/class of material demanded.

After checking these points, the purchase department compares the present rates in the market, forwards it to the director, and seeks the final approval of rates, delivery schedule, credit period, etc. The order for materials is then placed with the supplier as per building material requisition procedure.

Once the order is placed then the site in charge should be in continuous contact with the purchase department for delivery of material.

If the material is not received in a given time then the site engineer should prepare cumulative pending tendency for all the items demanded earlier.

|

| Requisition indent slip |

|

| Flow chart for requisition indent submission to purchase department |

4. PENDING REQUISITION OF MATERIAL

- This is to be written in a printed format that is sent to H.O. and 2nd copy to be retained on site. Pending indents should be sent once in a week for all the materials which are due for delivery.

- If the material is pending but not required due to certain changes in the work program, then the site engineer should clearly write a note on the pending indent for the next delivery schedule.

- All site engineers shall discuss with Purchase Manager once in a week to sort out the problems about delivery/ quality/ urgency/priority of material, etc.

INVENTORY CONTROL

Periodical inventory of the tools, equipment, and materials should be taken on every site to know the exact position and condition of the materials, tools, and plant. It helps in the following ways.

- Any excess material not presently required can be shifted to other sites for utilization.

- Before writing any requisition previous balance quantity may be accounted for and an order may be placed for balance quantity.

- Any shortfall or damages to the material can be informed to the higher authorities.

- Repairs or modifications of storing systems can be done if required.

- Cross-checking of the records maintained by the storekeeper.

- Consideration of the percentage of wastage for various materials should be studied and standardized to avoid excess inventory.

Purchasing of the material in stages as per the work program should be followed to avoid additional financial load for excess inventory during that period.

Also, Read This

Thank you its informative