In undeveloped areas, where Municipal sewers are not yet laid and where there are no facilities to carry and treat the sewage in the public sewage treatment; How septic tank work is constructed for satisfactory disposal of the sewage from these isolated buildings, septic tank design.

1. WHAT IS A SEPTIC TANK?

- It is a plain sedimentation tank.

- A biochemical reaction by anaerobic bacteria takes place here.

- Sewage is detained in the tank in 3 zones

- (i) sedimentation

- (ii) digestion

- (iii) storage.

- Effluent is taken to the soak pits for disposal.

- Gases are produced during the digestion period of sludge. So, septic tanks are provided with a cover at the top.

How Septic Tank Work ppt Pdf Download Link Below

2. DESIGN OF SEPTIC TANK?

For designing of the septic tank, it’s capacity is calculated as per the number of users. liters/ person per day is considered with a detention period of 24 hours, for sedimentation, on an approximate basis. From the total volume known. the length of the tank is kept 3 times its breadth.

The depth of the tank is taken as 1 to 1.25m. The scientific design is used as per provisions in I.S.

3. CONSTRUCTION OF SEPTIC TANK?

- Septic tanks are constructed with corrosion-resistant materials.

- Normally 23cm (9″) thick brick masonry is adopted for the construction of the tank. However, for waterlogged areas and for deeper depths, R.C.C. raft and side walls are recommended over the P.C.C.

- P.C.C. at the bottom is on the slope of 1:10.

- The bottom and the inner faces of the tank are water-proofed to make it watertight.

- Inlets and outlets are provided with submerged pipe tees, to avoid direct contact between the two.

- Baffle walls should be constructed near the inlet and outlet ends, to prevent the direct flow of sludge.

- The center of the outlet pipe is kept 150mm below the center of the inlet pipe.

- Design the height of the tank to allow at least a 40cm freeboard.

- Cover the top of the tank with a slab, by keeping manholes to each compartment.

- Fix the vent pipe in the top slab.

- Cast-Iron steps may be provided in the tank to facilitate entry inside.

- Ready-made NP2 Hume-pipe septic tanks are available in the market. They are practical for small bungalows and buildings. available as per the requirement i.e. as per the number of users.

- The modern technology of ferrocrete has developed in the construction of septic tanks with Ferro cement. They may be in the form of round pipes or rectangular tanks. Due care should be taken to design for proper loading.

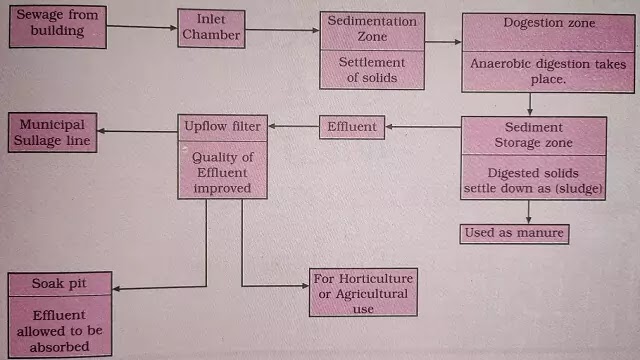

4. FUNCTIONING OF SEPTIC TANK AND HOW SEPTIC TANK WORK

How septic tank work can broadly be divided into three zones, according to the stages of treatment on the receiving sewage.

- Sedimentation zone

- Digestion zone

- Sludge storage zone

STAGES OF FUNCTIONING

- All sewage from the building is collected in a sewer chamber provided with a sewer trap.

- The inlet of the septic tank is S.W. tee placed horizontally so that the tee head remains vertical.

- The sewage falls down through this tee. Sometimes bends are also used.

- The sewage comes in the first zone and solid particles are allowed to settle over a prescribed detention period.

- Due to the unavailability of free oxygen, the anaerobic action takes place in the second zone. The organic part degenerates into liquids, gases, and residual mineral solids.

- In the third zone, the solids settle at the bottom and are called the sludge. It should be removed periodically (at an interval of 1 to 2 years) and used as manure.

- The effluent is disposed of in the soak pit or to the up-flow filter chamber for further treatment.

- 25 to 30% B.O.D. is removed from the septic tank.

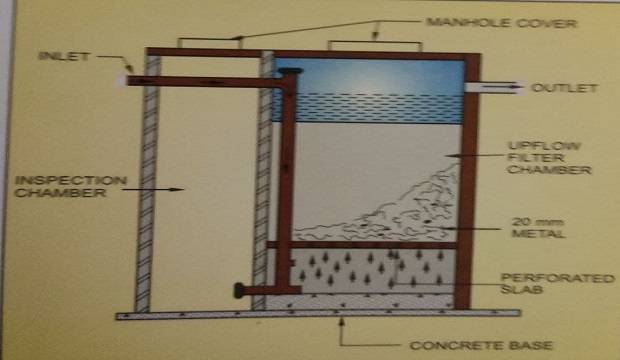

5. UPFLOW FILTER CHAMBER

The effluent from the septic tank is allowed to pass through a filter media, to improve its quality, and then it is disposed of.

This up-flow filter is designed to take the effluent directly to the bottom of the tank and then it passes upwards through a filter media of 20mm stone chips, placed compactly above a false R.C.C. bottom with sufficient openings.

The outlet of the up-flow filter chamber is connected to the soak pit or to the Municipal sewage line. An inspection chamber should be provided for cleaning the sludge deposit in the up-flow filter chamber.

The bottom of the up-flow filter chamber should have a sufficient slope towards the cleaning outlet.

Proper functioning of the up-flow filter can remove B.O.D. (Biochemical Oxygen Demand) up to 85%.

6. SOAK PIT

The effluent discharged through the outlet of the septic tank is disposed of through the soakage gallery or soak pit.

PROCEDURE OF SOAK PIT?

- A spot is selected away from human habitats.

- It is a hollow, circular/rectangular pit.

- The depth of the soak pit varies between 120cm to 180cm.

- The pit need not be constructed in case of hard strata but for loose strata, the brick lining should be done without plastering.

- Loose brickbats are laid at the bottom to improve the soaking quality.

- Effluent falls in the pit- and is allowed to be absorbed in the surrounding soil.

- The design is based on the actual site percolation test.

7. SULLAGE LINE (MUNICIPAL DRAINAGE LINE)

All the treated effluent is finally connected to the Municipal sullage line as per the availability of such lines. All such connections are done by the plumbing work contractor, with prior approval from the municipal authorities.

After this connection, a ‘No Objection Certificate’ (N.O.C.) should be obtained from the Municipal authorities before the septic tank is functional.

Normally this sullage line is of hume pipe, NP2 class, and about 45cm (18″) in diameter. Manhole chambers @ 30m intervals are provided.

This sullage line ends either in river water or into the corporation sewage treatment plant, depending upon the contents and nature of the effluent.

8. MAINTENANCE OF SEPTIC TANKS?

- Since sludge is allowed to accumulate at the bottom of the tank, the capacity of the septic tank reduces. Therefore, septic tanks should be cleaned every 6 to 12 months or as per the designed period for cleaning.

- The tank should be filled with water, at the time of making it functional.

- The effluent from the tank should be properly disposed of. Brickbats in the pit should be changed periodically.

- Avoid the discharge of effluent in natural water bodies.

- All chambers and the inlet and outlet pipe should be cleaned periodically to avoid choke-up in the system.

9. FLOW CHART FOR SEPTIC TANK?

|

| septic tank flow chart |

10. TYPES OF SEPTIC TANK

Septic system design and dimension can differ, from inside your neighborhood to throughout the nation, because of a mix of things. These components household, size soil type site slope, lot dimension, proximity to delicate water our bodies, climate circumstances, and even native rules. Below are ten of the commonest types of septic methods used. The checklist just isn’t all-inclusive; there are a lot of different types of septic methods.

- Septic Tank

- Conventional System

- Chamber System

- Drip Distribution System

- Aerobic Treatment Unit

- Mound Systems

- Recirculating Sand Filter System

- Evapotranspiration System

- Constructed Wetland System

- Cluster Community System