1. READY MEXED CONCRETE PROCESS RMC

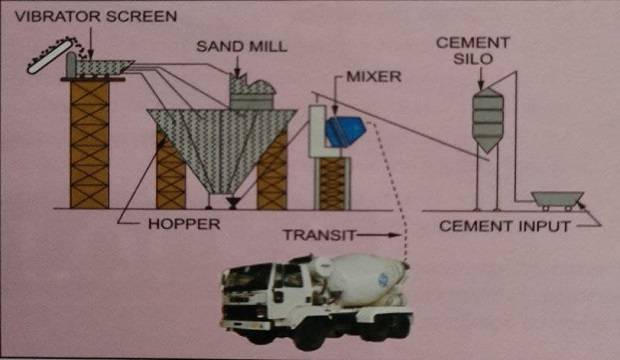

Ready mixed concrete process (R.M.C.) is the fresh concrete mix, which is produced by weigh-batching ready mix concrete manufacturing plant.under complete quality control and delivered duly mixed to the site of placement by truck-mounted agitators or dumpers.

Types of Ready Mixed Concrete Rmc

- Transit mixed concrete

- Shrink mixed concrete

- Central mixed concrete

1. Transit mixed concrete

The amount of mixing in the transit mixer depends upon the extent of mixing done in the central ready mixing concrete plant. Tests should be conducted to establish the requirement of mixing the drum concrete mixer.

2. Shrink mixed concrete

Concrete is partially mixed in the plant mixer and then balance concrete mixing is done in the truck-mounted drum mixer during transit time.

3. Central-mixed concrete

While transporting the mixed concrete, the truck mixer acts as an agitator only. Sometimes, when the workability requirement is low or the lead is less, non-agitating units or dump trucks can also be used in manufacturing ready mix concrete plants.

For the production of ready mixed concrete process India supplier, the following components are required.

WHAT IS READY MIX-CONCRETE | RMC PLANT | IN HINDI

- CENTRAL WEIGH BATCHING PLANT

The plant where all the preliminary operations and tests are carried out is the weigh batching plant. The location of the plant will depend upon the distance of the quarry of aggregates and water supply etc.

- CEMENT INPUT AND DELIVERY

For this purpose, a silo of a certain capacity (about 30t) is erected at the central manufacturing ready mix concrete plant.

- AGGREGATE COMPARTMENTS

For the storage of aggregates, three to four compartments are provided. These compartments feed the respective weight bins.

- PLANT

The capacity of the plant for a normal quantity of concrete Indiansuppliersis about 20 to 30 cum. concrete per hour at an optimum level of operation.

- WEIGHING DEVICES

At the crucial point in mix design, weighing devices are necessary. These devices are calibrated periodically.

- LABORATORY

The laboratory is the most important unit in the ready-mix manufacturing plant. This is provided for the mix design and for any changes to be made. Slump tests, cube tests, etc. are carried out here.

- TRANSIT MIXER

It is provided on the truck and rotates at a speed of 13 revolutions a minute and keeps the green concrete in an agitated state. During travel, it has facilities to mix water of measured quantity.

- PUMPING OF CONCRETE

Pumping concrete saves a hugely human effort. During the casting of the slab, many laborers are required.

TEST CARRIED OUT ON READY MIXED CONCRETE RMC

3. NEED OF R.M.C. AT SITE

There are many uncertainties in site mixed concrete such as.

- Inferior quality of sand at the site with more silt content.

- Aggregates received at the site may be oversized and due to an emergency cannot be refused, which ultimately affects workability.

- Cement brands may differ.

- Laborers are not available on the scheduled dates.

- Corporation water is available only for a particular time. So, extra provisions for water are to be made.

- The mixer or lift may not be working properly, affecting the continuity of work.

- The electricity board may suffer major breakdowns, holding up the work.

From the above points, it can be concluded that ready mixed concrete procedure, price Pune is important when adopting and controlling the quality of concrete.

4. ADVANTAGES OF READY MIXED CONCRETE – RMC

- Good quality concrete of uniform consistency under controlled conditions is produced.

- Faster concreting is possible due to the automatic and continuous operation of the manufacturing ready mix concrete plant.

- Supervision and labour costs can be reduced.

- The storage of cement is eliminated. This is very important as cement reduces its strength if stored for a long time.

- Wastage in cement handling is reduced.

- Bulk procurement of cement at a central ready-mixing concrete plant will be more economical due to.

- Higher bargaining power

- Smaller inventory

- Bulk handling of cement avoids packing cost

- When aggregate is stored on the ground, mixing with soil can be avoided with a central material manufacturing ready mix concrete plant.

- Maintenance of a single unit is easier and more reliable than a number of machines working in scattered locations.

- In the case of congested localities, storing materials and carrying out mixing operations is difficult. here, ready mixed concrete procedure, price India supplier is the best solution.

- In the case of site mixed concrete, more labour force is required. This disturbs the reinforcement and can be avoided since for R.M.C. less labour is required.

What are the disadvantages of ready mixed concrete procedure plants?

- If travel time increases concrete is damaged.

- Increased water content in concrete is weak.

- Communication is wrong than the upcoming concrete grade change.

- If the electricity problem than a plant can not work

IF YOU LIKE THIS POST-READY MIXED CONCRETE PROCESS – TYPES AND ADVANTAGES LIKE THIS GETTING GOOD INFORMATION SO PLEASE SHARE THIS POST-SOCIAL NETWORK EXAMPLE FACEBOOK, TWITTER SOCIAL MEDIA SITES SHARE IT.

Also, Read This